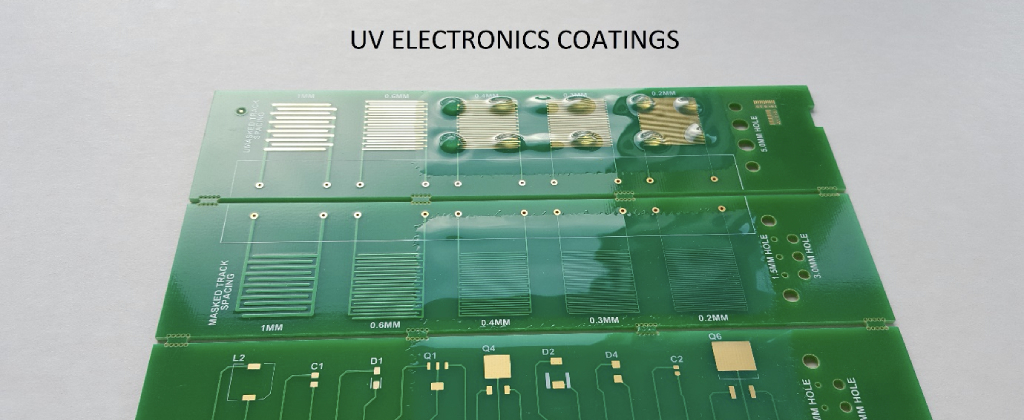

Chemistry for Graphics industry. UV light – UV cure/ paint / coatings

NEW ZEALAND UV CURE SPECIALISTS – UV and aqueous environment friendly

Our Eco-friendly products feature UV Cure and water-based chemistry for all the fields below. These are the alternatives to polluting and unhealthy solvent-based products.

For all application methods: Roll coat, curtain coat, vacuum coat, spray lines, mobile curing lamp systems (link to CIP) etc.

Quick-dry Aqueous paint for professional painters – get multiple coats done in a day.

UV Roll-coat: Clear gloss, matt, satin, or pick your colour. We have standard colours and can colour match for you. Let us demo for you.

Vacuum coat: So you need to coat all 4 sides of a moulding – this is the best way, UV or Aqueous. We can put you onto machine manufacturers.

Curtain coat or spray: Get the ultimate wet look gloss finishes.

Flooring systems: UV sealers, wear resist and scratch resist systems for machine application – or cure-in-place (CIP) systems. We can help you with equipment.

CONTACT US to design a product for your end

CONTACT US – GO AHEAD MAKE YOUR PROBLEM OURS.

UV curing has an unending number of uses which capitalise on the high speed of cure and film build which can be achieved with 100% solids materials.

These are liquid at room temperature but are converted entirely to a solid under UV light, without the need for an evaporation phase in the drying process.

Some examples are